Mar 30, 2024

EFFECT OF ROLLER MILL ON THE GRINDING STABILITY OF WHEAT MILLING

Edit by:www.immy.cn

.png)

The roller mill is the core host of wheat milling, and its stability directly affects the grinding stability of the mill, which is the fundamental guarantee of the overall flow balance and milling quality of the milling production line, and is an important technical index to measure the overall performance of the mill. The main factors affecting the grinding stability of the mill are not only the mechanical structure of the mill itself, but also the moisture, quality, particle size and equipment operation of the grinding material will affect the grinding stability of the roller mill.

With the continuous improvement of people's living standards in the new era, consumer demand has shifted to "eat well", "eat safely", "eat healthily" and "eat conveniently". The terminal market has higher and higher requirements for flour quality, the variety of special flour is increasing year by year, high-end flour is gradually seizing market share, the market competition is becoming more and more intense, the new contradiction between supply and demand effectively promotes the rapid development of the milling process in the direction of meeting the contemporary market demand, the longitudinal and horizontal flour road extension of the milling process, the light grinding fine grinding and fine grinding effectively improve the grinding rate and the processing accuracy of the flour, and also provides the basic conditions for the production of special flour, and the modern milling process also puts forward new requirements for the grinding stability of the mill.

_%E5%89%AF%E6%9C%AC.png)

1 Effect of Wheat Maize Flour on Grinding Stability

The feeding system, grinding system and cleaning system of the mill have a great impact on the grinding stability of the mill, and the uniform and stable feeding is the basis of stable grinding, and the effective and reliable cleaning system is a necessary condition for grinding.

1.1 Feeding system

The feeding system, also known as the feeding unit, is mainly to stabilize the relative level height of the material in the feed barrel, and feed the material into the grinding area at a certain speed evenly and accurately along the entire roller length direction [1], and grind the material by the grinding system.

(1) When feeding, it is necessary to ensure that the material is evenly spread throughout the feeding area, when the material can not be effectively spread over the feeding area and reaches the minimum material level setting value, the grinding unit should be able to leave the rolling and stop feeding in time to avoid damage to the surface of the grinding roller of the core components in the grinding system due to the empty feeding of the material.

(2) The thickness of the material feeding layer should be consistent to avoid the phenomenon of local thickness difference caused by thin one side and thick one side, broken flow of the material layer or superposition of the material layer.

(3) According to the process requirements, sensitive and accurate adjustment of the feeding amount, when the material in the feeding bin fluctuates, the feeding amount can be automatically adjusted within a certain range to ensure the continuity of feeding and the relative balance of the overall process of materials.

(4) Under the logic control of the automatic control system, it can realize the reliable sequential relationship of "feeding first and then rolling together, and first leaving and then breaking the material" with the clutch rolling mechanism of the grinding unit.

(5) For the mechanical servo feeding system, the feeding door opening degree is controlled by the float type mechanical sensing servo to balance the material, so as to avoid the instantaneous increase or decrease of the feeding door opening, resulting in a sharp change in the thickness of the material and affecting the grinding stability.

(6) For the electronically controlled automatic feeding control system, the level height (such as: capacitive level sensor, photoelectric level sensor, gravity sensor) is identified by the electronic level sensor and the speed of the feeding roller to establish a certain logical relationship, according to the material situation of the feeding barrel, adjust the feeding speed to balance the material, and when changing the feeding speed, it is necessary to avoid the instantaneous increase or decrease of the feeding speed, resulting in a sharp change in the feeding amount and affecting the grinding stability.

1.2 Grinding system

The grinding system is the key part that affects the grinding effect, is the core of the mill, also known as the grinding unit, in the grinding system, the middle convexity or taper of the grinding roller, the dynamic imbalance of the grinding roller, the radial runout of the grinding roller, the stiffness of the parts and structures have an important impact on the grinding stability.

1.2.1 Medium convexity or taper of the grinding roller

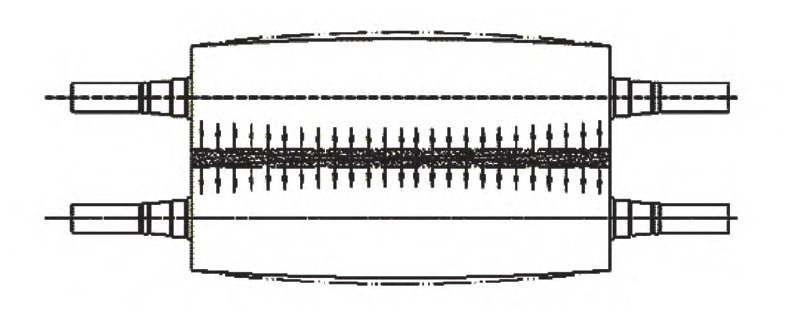

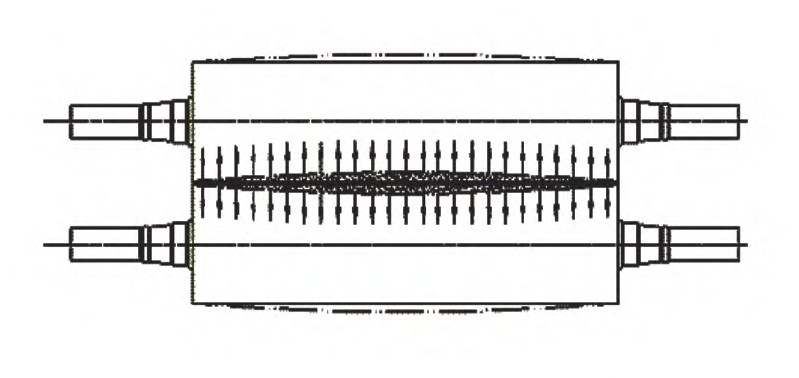

When grinding materials, the rolling distance between the rollers is generally 0.05~0.2 mm, and the roller has a large inter-roll pressure during grinding, and the bending strain will occur in the whole length of the roller body under the action of grinding force, and the strain is proportional to the pressure between the rollers[2] In addition, when grinding the roller, the maximum heat is generated near the bearing, and the outward expansion of the roller at both ends is slightly greater than that of the middle, and the microscopic deformation of the roller body occurs due to the influence of bending stress and thermal expansion, which has a greater impact on the grinding stability and production, so it is generally necessary to compensate for the influence of deformation on grinding by the convexity or taper in the prefabrication when grinding the grinding roller. As shown in Figure 1, the "grinding zone without medium crown or taper compensation value of the roller body" is in the shape of a jujube kernel with a large middle rolling distance and gradually decreasing at both ends, and the rolling distance between the rollers is kept uniform when grinding the material when grinding the material.

Wuxi Hasen Import And Export Co.,Ltd

Contact:Amina Zhu

Mobile:+8613812016908

Email:sale@immy.cn

Add:#68,Xindongan Rd,Xinwu Distt,Wuxi,Jiangsu,China 214000